Comparative studies on mechanical properties of WC-Co composites sintered by SPS and conventional techniques

MATEC Web of Conferences(WoS), 2017, Volume 129, Article Number 02028

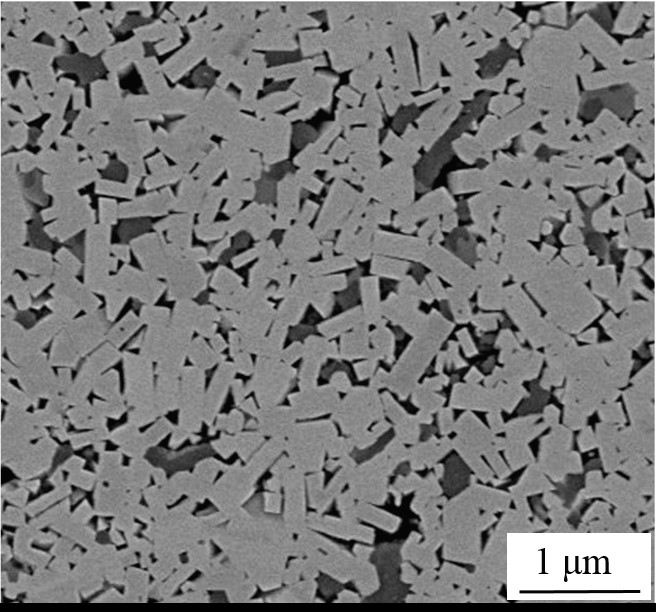

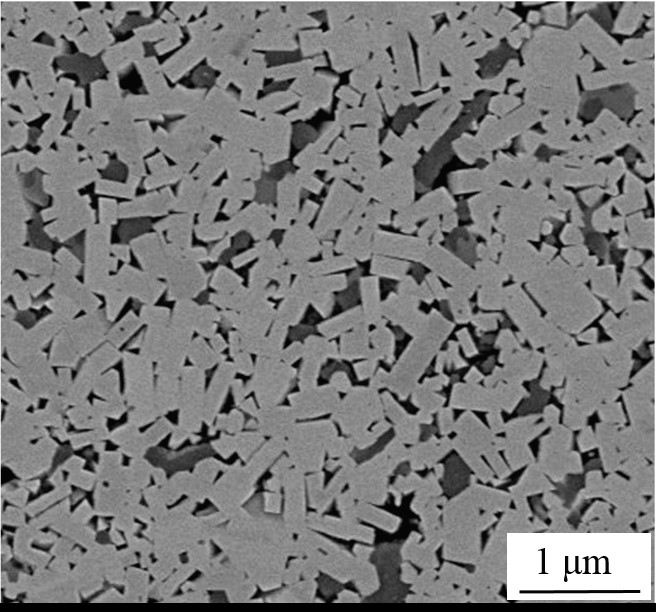

Abstract. Spark plasma sintering (SPS) is an extremely fast solidification technique for compounds that are difficult to sinter within the material group metals, ceramics, or composites thereof, SPS uses a uniaxial pressure and a very rapid heating cycle to consolidate these materials. With SPS the main benefit is the ability to control the WC grain size due to the short sintering times at high temperature. Additionally, its allows to avoid negative reactions between WC and cobalt and to minimize the formation of undesirable phases in sintered composites. The WC-6wt.% Co cermet prepared by SPS processing achieves the enhanced mechanical properties with the hardness of 18.3 GPa and the fracture toughness of 15.5 MPa·m1/2 in comparison to standard reference tungsten carbide/cobalt material.

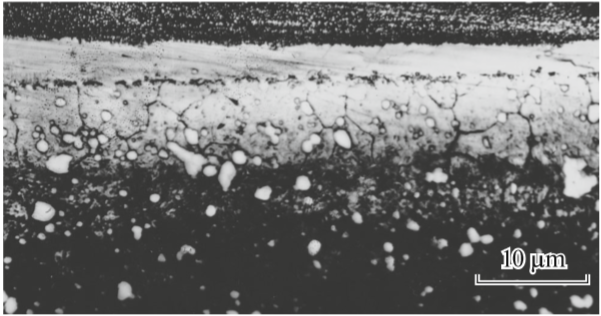

SEM images of polished and thermally etched sections of SPS sintered (1300°C/10min/80MPa) WC-6% Co cermet. Light grey phase is carbide particles.

Исполнители: Y. Pristinskiy, N. Peretyagin, W. Solis

Дата публикации: 07-11-2017

Источник: https://www.matec-conferences.org/articles/matecconf/abs/2017/43/matecconf_icmtmte2017_02028/matecconf_icmtmte2017_02028.html